Valio is Finland’s leading dairy company. It’s owned by a co-operative of Finnish farmers who promote milk production without genetically modified organisms, animal and employee well-being, and the manufacturing of healthy foods such as milk powder. Valio lives and breathes sustainability and strives to be one of the best organizations in the world when it comes to cleanliness, water footprint, and its overall effect on the climate.

Several years ago the Valio Seinäjoki plant started to plan a new layout for the packaging area including a new milk powder filling line. Arodo was chosen as a partner for the development of an innovative milk powder bagging machine.

Milk powder bagging machine: innovation is key

Founded by farmers in 1905, Valio pays its profits to owners via the price of raw milk. The company has an excellent Research and Development department, which was headed by Chemistry Nobel Prize winner A. I. Virtanen from 1921-1970. Under its umbrella of achievements, we can especially highlight its patented nutritional innovations, such as lactose-free Eila© and milk salt ValSa©, which are sold internationally.

Speaking of international – Valio has production plants in 12 cities in Finland, 2 in Estonia, and 1 in Russia. Subsidiaries are found in Sweden, Russia, Baltic countries, the USA, and China. Valio employs 4,000 employees and made a net turnover of €1,7 billion (2017). Valio's mission is to make life better together. The mission is to expand the well-being of customers far beyond Finland with high-quality Finnish milk, milk powder, sensational flavors, and technological innovations.

Just like Valio’s mission “together we make life better”, the partnership between Valio and Arodo was a perfect match. In 2012 the plant in Seinäjoki was planning a new layout for its milk powder packaging area. The goal was to separate the milk powder filling line from the palletizing area, to further improve the hygiene level in production, and also to produce with a higher capacity. Valio was impressed by Arodo’s good references, our excellent design, and our competitiveness, especially paired with our high-quality standard.

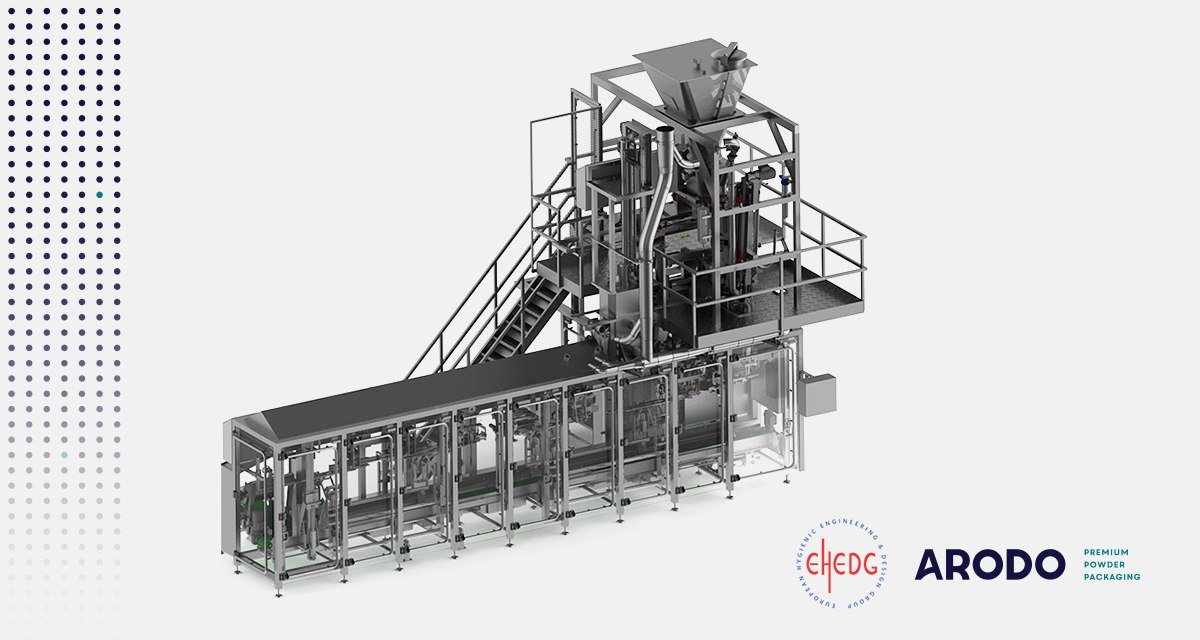

Milk powder bagging machines with vacuum technology

Valio was looking for a way to optimize its packaging area for bagging milk powder. Previously, Valio did face a lot of issues, related to air in the bags and low capacity on the existing milk powder filling line. Bags with air need pinholes in the inner liner to evacuate the air.

Together with Valio, we analyzed the situation and created the perfect solution: a milk powder bagging machine to pack milk powder in bags without adding air, and this by using the AROVAC® vacuum technology. The result: more efficient production, stable stacked pallets, and compact bags that can be weighed extremely accurately.

In addition, no more openings are needed in the bags to allow excess air to escape. Products, such as milk powder, have a longer shelf life. Our AROVAC® technology also has a positive influence on the smell, color, and taste of the milk powder. With AROVAC®, Valio thus benefits from maximum protection and carefree transportation.

Milk powder packaging: long-lasting collaboration

Valio was so happy with the collaboration with Arodo during the planning and implementation stages that the cooperation didn’t stop there. We have been tasked with providing the annual maintenances and Valio can use Arodo´s 24/7 hotline and spare parts service. Since 2012, the partnership between Valio and Arodo has developed into a success story, with a wide range of machine deliveries. Several bag filling lines with milk powder bagging machines, palletizers, and stretch hooders are installed at Valio. Besides the milk powder bagging machines, we are also a preferred supplier for several special solutions for big-bag filling lines. The two big-bag machines are developed according to hygienic design and easy cleaning standards.